Making a Press

The following information is taken from the out-of-print Agriculture

Canada booklet # 1406 which was scanned by Bill at the

Squeeze

Cider Press (now closed) on Vancouver Island. You can read

the entire leaflet here. The full leaflet also contains details

of how to make a mill at home, how to make and sterilise juices, and

how

to make straightforward fermented fruit wines and ciders.

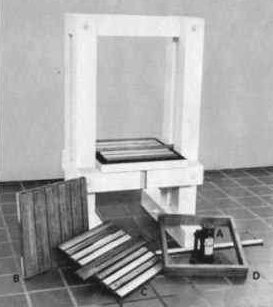

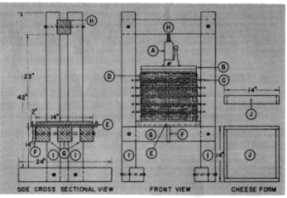

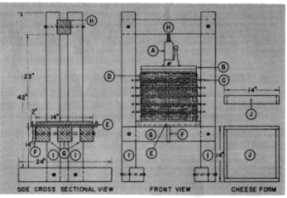

Here are the details of the press:

A,

Hydraulic jack, 1 1/2 tons capacity, 8-in, lift.

A,

Hydraulic jack, 1 1/2 tons capacity, 8-in, lift.

B, Jack support, a 14 x 14-in, piece of 3/4-in, fir plywood

or hardwood with 6 slats 1/4 x 1 in. nailed on one side.

C, Racks. Five racks 14 x 14 in. are made from 1/4 x 1-in,

slats of hardwood nailed to 1/4 x 1 1/2-in, slats at the edges. The

center

slat is 18 in. long and serves as a guide between the uprights, I. It

is

2 in. wide and has a center slot. The nails are stainless steel.

D, Press cloths of medium factory cotton are about 36 in.

square.

E, Press base is a 17 x 17-in, piece of 3/4-in, plywood

fastened

to supports G. A 14 x 14-in, piece of 1/2-in, plywood is centered on

the

larger piece to channel the juice to the outlet, F. Four slats 1/4 x 1

1/2 in. on edge form the sides around the base.

F,

Juice outlet made of 3/4-in., acid- resistant or plastic pipe.

G, Supports for press base.

H, Press top is of hardwood or fir plywood with a metal plate

at the point of contact of the jack.

I, Uprights are reinforced with 1/4 x 4-in, metal strapping

across the press top and 20 in. down two sides. All uprights and cross

pieces are made of 4 x 4-in, fir.

J Cheese form is 2 x 14 x 14 in. and is made from 3/4-in,

hardwood. All wooden parts of the press that come in direct contact

with

the juice are coated with hot paraffin.

Boil new cotton cloths in water for 5 min and rinse. Dampen them

before use. After each use, wash the cloths thoroughly by changing the

water often and dry them well before you store them. To use the press,

place a rack on the press base. Put the cheese form on the rack and

cover

both with a press cloth. Pour the product to be pressed on the cloth,

as

shown, to make a cheese 2 in. thick. Fold the cloth neatly into the

center

of the cheese and remove the

cheese form. Place

another rack above this cheese and repeat the procedure until there is

only space for the jack support, B, and the jack. Center the jack on

the

jack support and apply pressure evenly.

Note there's a similar set of plans and a clearer diagram given in

the

Proulx

and Nichols book

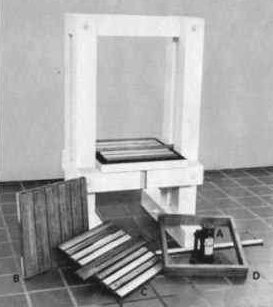

My own press was virtually

identical

to this except that it's somewhat scaled up. I used 6" square

ash timbers, an 18" square set of racks and cheese form (to give a 16"

square press area) and an 8 tonne jack. Here's the press in action.

People often ask about the pressures and yields associated with these

sorts of pack presses. A rough guide from calculation and my own

experience is as follows:

- The original Canadian design (above) with 12.5" effective square

cheese and 1.5 ton jack gives 22 psi.

- My home-made variant with 16" effective square cheese and a 2 ton

jack gives 120 kPa or 17 psi and a juice

yield ca 60%. This is a low

yield, and I often used to re-wet the pomace (add about 10% by weight

of water) and re-press when I was using this jack, to improve the yield.

- The same with a 4 ton jack gives 240 kPa or 35 psi and a juice

yield of about 65%

- The same with an 8 ton jack gives 480 kPa or 70 psi and a juice

yield of about 70%. Generally I didn't find it was worth wetting

and re-pressing the pomace once I was using this jack.

- A commercial steel-framed hobby hand screw press (like Vigo)

gives ca 788 kPa

or 115 psi

- My commercial Voran press (steel frame and electric hydraulics)

gives

952 kPa or 138 psi. JuiceYield ca 75%.

Yield is not a linear function with pressure and only increases by

about 5% with each doubling of the pressure. If possible it's

worth aiming for a minimum 70% juice yield and hence a minimum pressure

of about 70 psi. When you get to double that (like the commercial

press at 138 psi) you can get adverse effects like pulp oozing through

the press cloth if you're working with soft dessert fruit . So

excessive pressure is not necessarily a good thing. The

other thing that influences yield is time. Most of the juice comes out

fairly quickly but if you can maintain the pressure for several hours

you can get a useful extra few % of juice. It all depends on how

desperate you are and how much fruit you have!

Making a Mill

I've never made a mill - it seems

to

call for abilities in metal working which I don't possess. But

the

Ag-Canada

leaflet gives details of how to make one. An alternative very

neat idea using a garbage disposal unit was posted by Donald Yellman in

# 789 of the Cider Digest, and is reproduced below.

Subject: Applegrinding with Garbage Disposal

From: Donald Yellman

Date: Sun, 24 Jan 1999 00:06:16 -0500

The following idea was submitted to "Pomona", the quarterly journal

of the North American Fruit Explorers Association, Chapin, Ill..

While

I have not yet received the winter 1999 edition of that journal, I

have

been informed by cidermaker Bob Capshew of Indiana that the article

appears there. Bob suggested that I share the idea with Cider

Digest.

I also contacted Andrew Lea of Oxford, England, a well known hobby

cidermaker who thought the idea worth sharing.

For several years, I have been using a

kitchen

garbage disposal to

grind large quantities (12-15 bushels) of cider apples from my orchard,

having found the hand-cranked barrel grinder that came with my cider

press to be slow, wasteful, and generally inefficient.

Because the

concept of using a garbage disposal seemed so simple, it did not occur

to me until recently that I might be the only one doing this.

I can

only apologize for not having shared this as soon as I discovered that

it worked so well. And it does. It works and it's cheap.

All that is required is a table frame

constructed

of 2x4's or any

scrap lumber, about 36" tall, with a plywood or formica top about 2

feet

square. At least one side must be completely open to insert and

remove

a 5 gallon plastic bucket. Use a sabre saw to cut out the

appropriate

size hole in the center of the top, and install the (preferably new)

garbage disposal. The 90 degree plastic fitting that accompanies

the

disposal is perfect for discharging directly to the bucket below.

No

additional tubing is required. A metal switchbox and an ordinary

light

switch may be installed in a handy location on the side of the table.

Three-wire cord must be used, since both the disposal and the switchbox

must be grounded. Otherwise, you may light up unexpectedly while

standing on a damp surface.

When I built my unit, I was not at all sure

the concept would work,

and I opted for the cheapest garbage disposal available --- a $30.00,

1/3 horsepower model. In retrospect, I wish I had gone a little

further

up the scale, perhaps to a 1/2 horsepower model. I would also

look for

the one with the largest throat, as we sometimes have to cut large

apples in half to fit them in. Garbage disposals are essentially

miniature attrition mills, which operate with small hammers, not

knives.

The apple (or pear, or anything) slurry is expelled by centrifugal

force, and is absolutely perfect for pressing, but use of a large,

fine-mesh nylon bag to line the bucket is essential. When you

lift the

bag out of the bucket to your press, you will find a substantial amount

of clear cider already in the bucket. Fortunately, the nylon

bags are

inexpensive, widely available, and tough enough to last for several

years. The volume of dry pomace that remains after pressing is

quite

small, indicating that juice yield is close to maximum.

The internal parts of even the cheaper

garbage

disposals are all

stainless steel, so a thorough cleaup with the hose is quick and easy.

I wish I could say that is all there is to

the story, but I cannot.

Garbage disposal motors rely on the liquid they process for cooling,

and

they are not really built for continuous duty. While you can

feed in

apples at an amazing clip, after 25-30 minutes the motor will overheat

and trip the internal circuit breaker. Then you must wait 10-15

minutes

before you can reset the breaker. Eventually I may burn up my

little

motor, but so far, so good. Even with these occasional breaks,

I can

still grind 3-4 times faster than the hand grinder, and turn out a

much

better product. Now I wonder whether a larger, more powerful

disposal

might be more inclined to take the continuous use. I have also

given

some thought to wrapping cooling fins around the motor, installing

a

small fan under the table, or drilling ventilation holes in the motor

case itself. But, since these are induction motors, with the

windings

right there under the case, I am loath to drill. A good motor

man with

a machine shop could probably figure out some way to solve the

overheating problem.

Meanwhile, if you are willing to take an

occasional

break to let

the motor cool down, you can grind a lot of apples in an afternoon

with

the disposal grinder.

Don Yellman

Great Falls, Virginia

Further Cider Digest correspondence on this

topic then followed, exploring the concept in a bit more detail:

Subject: re: Applegrinding with Garbage

Disposal

From: (Dick Dunn)

Date: 31 Jan 99 17:54:24 MST (Sun)

Donald Yellman described his very clever

disposal-

grinder setup. I'm certainly game to try

it myself since I've not been

happy with the texture I've been getting from

the grinder on my press (too

coarse) nor the yield (almost always under 50%

in terms of juice-weight:

original-apple-weight). I've got some

questions,

which I'll post in hopes

the answers (from Donald or anyone else who's

tried this) will be of

general interest.

* The SS interior is an obvious Good

Thing

for sanitation, but do you

find that there are little

corners, holes, crevices that are hard to

clean of apple pulp and

bits?

Are we talking here about a device that

can be kept clean enough to

produce food-quality output? I don't ask

this in the sense of formal

regulations so much as I want to know if

you can get it clean enough

to produce fresh juice for short-term con-

sumption or freezing (as

opposed

to relying on the fermentation step

for dealing with pathogens).

* What is your processing rate?

You

mention having to stop periodically

to cool the motor, but you

were also talking in terms of a dozen

bushels (say five hundred

pounds) or so. For a lot of us, this isn't

going to be an issue since

we just don't press that much at a time.

For me, even if I did that

much in one day, it would still be cyclic

since I'd grind-and-press,

repeat. I wouldn't grind everything at

once. So, how fast can

you grind a bushel of apples?

* Do you notice any heating of the

pomace

after you've been running for

a while?

* Is there any problem with

clogging?

One of the characteristics of the

design of a disposal is that

it's meant to run with a lot of water

flow, which you won't

have.

Have you tried pears? That might be my

reference point for possible

clogging.

* Most disposals come with a flexible

shield

for the top, intended in

normal use to keep debris

from being ejected back out of the disposal.

(These shields also narrow

the effective opening.) Do you use the

shield, and if not, do you

have any trouble with blow-back?

* How is it with seeds? Does it

tend

to break/cut a lot of seeds?

> The apple (or pear, or anything) slurry

is expelled

by centrifugal

> force, and is absolutely perfect for

pressing,

but use of a large,

> fine-mesh nylon bag to line the bucket is

essential.

When you lift the

> bag out of the bucket to your press, you

will

find a substantial amount

> of clear cider already in the bucket...

Any thought about mounting the disposal so

that

it will feed directly into

the press basket of a small press? That

would require a downward

discharge, of course.

One other little note:

> The internal

parts of even the cheaper garbage disposals are all

> stainless steel...

Looking around at lumber/home-improvement

store

stuff (a lot of which is

low-end), I saw several with galvanized

interiors.

Don't think I'd want

that...zinc and apple juice sounds like a bad

idea. Caveat emptor--be sure

it's stainless before you buy.

Donald's reply was:

Subject: hygienic applegrinding

From: Donald Yellman

Date: Mon, 01 Feb 1999 14:05:06 -0500

Dick Dunn raises a very good point in digest

#790,

concerning use of a

kitchen disposal for grinding fruit, and that

is: be discriminating in

the type of disposal you buy.

1. All disposals are not created

equal.

The original disposal I have

used for grinding, the $30.00 model, is a "Grind

All". After some

disassembly and close inspection, I am now not

at all certain that all

the internal parts are stainless steel, although

the hammers clearly

are. The internal basket shows no sign

of corrosion, but it may well be

galvanized, that is, zinc coated. As long

as it is not cadmium plated

(which has a yellowish color), I don't know that

zinc is a problem.

Some apparently believe that zinc pills ward

off colds. Zinc has been

used to line food-grade containers for years,

but I understand that lead

is now out of favor. In any event, I don't

think the apples could pick

up much zinc on the way through, since they

travel

at pretty high speed.

2. I also inspected the dispoal in our

kitchen

sink, a much better

"ISE" model, which probably cost about

$75.00.

This one clearly has a

stainless steel throat, and I also noticed that

the throat is deeper,

that is, the distance from the surface to the

hammers is greater by at

least two inches. That is an advantage

in increasing the size of the

grinding chamber, and minimizing any

blowback.

On the discharge side,

all disposals come equipped with a 90 degree

plastic fitting that

changes the discharge angle from horizontal to

vertical, that is,

straight down. I originally thought I might

have some problems there,

and had purchased some additional tubing to

direct

flow into the bucket,

but found I did not need it. Not a drop

goes outside the bucket.

3. I have left the rubber blowback guard

in place on the "Grind All",

not least because it is a structural part of

the suspension, and if it

is removed the grinder falls out. That

is not true of the 'ISE'

disposal, which has a rubber guard that can be

inserted and removed from

above. I agree that operating without the

rubber guard is preferable

for hygienic reasons, and for marginally

increasing

the size of the

throat. I doubt that this would provoke

apple blowback, since the

apples move through there so fast, and there

is no backpressure in the

system.

4. One of my original concerns when I

built

the prototype, and the

reason I started with a cheap disposal, was

whether

ground apples would

pass through without additional liquid.

I am happy to report that they

do, and that clogging is not an issue.

5. I don't know what happens to the

seeds.

I never really checked for

them, and assume they are ground up with

everything

else. They don't

seem to add any off flavors, and as long as apple

and pear seeds are

non-toxic, I will continue not to worry about

them.

5. We do our apple grinding outdoors,

and

are able to able to use a

hose for rinsing when required. I have

also run the hose through there

to try to speed up cooldown of the motor, though

I don't know that did

much good. If you really wanted to clean

up the dispoal to USDA

standards, I guess you could put a rubber stopper

in the discharge, add

a little liquid and a non-foaming cleanser, and

throw the switch. I

think there might be some backpressure generated

with this procedure,

and I would stand back a bit until I was

sure.

Once again, it's not

something I would do in the kitchen, or my wife

would crown me, but it's

fine for the backyard.

6. We never really timed our processing

rate with a stopwatch, since we

were just having fun, but I would estimate you

could grind a bushel in

ten minutes or less, especially if you cut the

fruit in half first. A

larger, more powerful disposal would obviously

be faster. The pomace

does not pick up enough heat in its pass-through

to be noticeable, but,

again, I have not checked it with a

thermometer.

I have tried pears,

and it works as well as for apples. I think

even grapes would work, if

you wanted to increase the juice yield.

7. I guess you could design your unit to

discharge directly to your

press, as long as you can fit the press under

the table. I wouldn't

recommend trying to route the slurry with plastic

tubing or such, since

that might lead to some clogging and

backpressure.

The height of my

table, 36 inches, is merely a convenient working

height, which

discharges nicely into my bucket. Some

disposals may be longer than

others, reducing the clearance below, but the

height of the table

surface is up to you. Cidermaker Bob

Capshew

plans to use an old sink

to mount his disposal. That will work fine

as long as long as he can

still get a bucket under the unit. I

originally

considered using a sink

myself, but didn't happen to have one around,

and did have a piece of

countertop. It goes without saying that

one side of the table must be

completely open to insert and remove the bucket.

8. I say again, my experience is with

use

of fine-mesh nylon pressing

bags, which are readily available at winemaking

shops. I don't know

what your pressing basket looks like Dick, but

if it is lined with a

nylon bag it should work fine. The slurry

that emerges from the

disposal grinder is quite different from a hand

grinder, and therein

lies its juicemaking efficiency.

And then he added:

Subject: cider grinder redux

From: Donald Yellman

Date: Tue, 02 Feb 1999 00:14:55 -0500

I have had a few second thoughts since sending

off a msg in response to

Dick Dunn's queries. I understand

the risks of

beating a fairly good idea to death here, and

I may have to eat a few of

my words, but be it so. I've been eating

them all my life. It is

important that others avoid repeating the

mistakes

I have made.

1. I further disassembled my "Grind All"

disposal, and indeed, the

upper body is an aluminum casting, but there

was no evidence of

corrosion. Beneath the grinding plate,

which is galvanized steel, is a

reinforcing bar that holds the two riveted

hammers.

That bar is

apparently uncoated carbon steel. It should

be visible through the

discharge hole, before the plastic elbow is

installed.

The upper body,

which is sealed to the lower body with a large

o-ring, comes off quite

easily by removing the nuts from the four long

bolts that run through

the unit. The reinforcing bar did have

a light coating of rust. The

discharge chamber, below the grinding plate,

is also an aluminum

casting, but again, there was no sign of

corrosion.

I did find an apple

seed in there.

2. The motor of the "Grind All" is not

designed

to be further

disassembled. It is staked at several

strategic

points, and I cannot

even get the bottom plate off. Probably

just as well. It might be

difficult to get the lower bearing properly

realigned.

However, I could

see up to the ring electromagnet through the

hookup hole, and there is

1/2 inch clearance between the steel motor case

and the windings. I may

try to drill a series of cooling holes in the

lower part of the motor,

using a drill stop to prevent going too

far.

I don't know whether that

will have a significant effect on motor

cooling.

Frankly, I think a

larger motor is the answer.

3. I may have misunderstood Dick Dunn's

query about discharging

directly to his press. I was thinking only

in terms of a table or sink

mount, and could not figure out how Dick would

get his cider press under

a small table. My press is as high as an

elephant's eye. Dick may be

thinking of mounting the disposal directly to

the frame of his press.

That might work, but a disposal is a pretty heavy

object, and the

mounting would have to be quite rigid.

It is also easier to work, that

is to feed in apples, on a flat surface or a

sink at convenient height.

When I lift my full pressing bags to the press,

I bring the whole bucket

over to minimize drippage and loss. I don't

lose much.

4. A comeback from faithful cidermaker

John

A. MacLaughlin suggested

using a ground fault outlet for the grinder,

in addition to proper

grounding. That is an idea that I will

implement, since I always use

the same outlet from the garage, and a gfci

should

probably be installed

there anyway. John also suggested a fine

spray of water for cooling the

motor case. I am not certain I want to

spray an active electrical

appliance with water, although with the gfci

I could probably get away

with it. I might spray it down when the

power is off.

5. One other small thing.

Disposals

have a knockout for installation

of a dishwasher drain. Don't knock it out.

6. In sum, look over the disposals

carefully

before buying, and choose

the one with fewest corrosive internal parts,

the largest throat, and

the most profound grinding chamber. I have

to confess I never gave

these things much thought before getting all

this feedback. Although I

am a fiscally conservative, not to say cheap,

consumer, I may even buy a

better disposal myself.

Regards, Don Yellman

Back to Andrew's Milling

and

Pressing page

Last updated 23 September 2000

A,

Hydraulic jack, 1 1/2 tons capacity, 8-in, lift.

A,

Hydraulic jack, 1 1/2 tons capacity, 8-in, lift.